Product Description

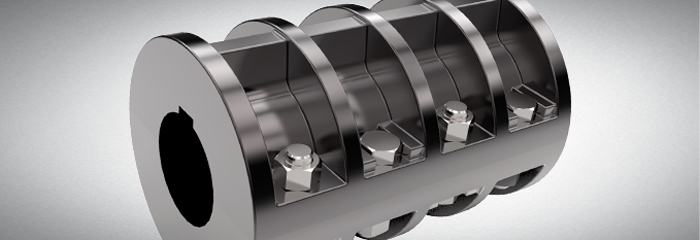

Custom Stainless Steel External Thread Hose Fitting Pipe Nipple Clamp Coupling

Product Description

The quick fitting leather pipe joint adopts fine internal and external polishing to meet the surface precision requirements; The feeding adopts a strict quality inspection system to ensure excellent quality. Beautiful appearance, smooth surface, acid and alkali resistance, anti-corrosion, strong texture performance, widely used in dairy products, beer, wine, biotechnology, food, pharmaceuticals, beverages, cosmetics and chemical industries.

ADVANTAGES

1. High strength: The welded pipe undergoes multiple processing steps and is made of a whole section of steel plate, thus having higher strength.

2. Excellent sealing performance: Due to the lack of joints in the welded pipe, it has better sealing performance.

3. Easy to make: Welded pipes can be made into specific lengths and shapes according to needs, with high flexibility.

4. Economical and practical: Compared with seamless steel pipes, welded pipes have lower manufacturing costs and are more economical and practical.

Product Parameters

| Item | Quick Fitting Leather Pipe |

| Warranty | 1 Year |

| Customized Support | ODM/OEM |

| Brand Name | AOMITE |

| Technic | Forged |

| Material | Stainless Steel 304/316L |

| Size | 1/2 inch-4 inch,Customized |

| Application | Dairy, food, beer, beverage, pharmacy, cosmetic, etc |

Detailed Photos

Company Profile

HangZhou Xihu (West Lake) Dis. Xihu (West Lake) Dis.g Xihu (West Lake) Dis. Fluid Equipment Factory is located in HangZhou Valve City, 1 of the valve bases in China. It is 3 kilometers away from HangZhou Airport, 4 kilometers away from Zhuangyuan Port, and 15 kilometers away from HangZhou Railway Station. The transportation is convenient, the logistics are developed, and goods directly reach all parts of the country. Our company is a professional manufacturer that integrates design, development, manufacturing, engineering installation, and after-sales service, specializing in a series of sanitary fittings, valves, and other products. The products are widely used in fields such as dairy products, beer, food, pharmaceuticals, beverages, cosmetics, and chemical water treatment. The company always focuses on high quality, with the goal of striving for excellence, and is committed to fierce market competition, strictly guided by market requirements. Business purpose: “Quality first, customer first”. Long term implementation of the user principle of high quality and low price. We sincerely welcome new and old customers to call and write to negotiate orders. On this occasion, we would like to extend sincere greetings and gratitude to new and old customers!

FAQ

Q1: Where is the main market for your product?

A: We hope to do business with companies around the world. At present, our valves and fittings have been exported to North America, South America, South Asia, Europe, and the Middle East.

Q2: What are your main products?

A: We specialize in the production of various sanitary grade valve pipeline accessories, joints, clamps, tees, elbows, etc.

Q3: How do you ensure the quality of your products?

A: Before mass production, we have pre-production samples. A final inspection must be conducted before shipment.

Q4: What is your packaging like?

A: 1. Plastic bag → 2. Paper box → 3. Plywood box Or communicate packaging.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can Clamp Couplings Be Used in High-Temperature or Corrosive Environments?

Yes, clamp couplings are designed to be versatile and can be used in a wide range of environments, including high-temperature and corrosive conditions. However, their suitability depends on the specific material and coating used in the construction of the coupling.

In high-temperature environments, clamp couplings made from materials such as stainless steel or high-temperature alloys are commonly used. These materials have excellent heat resistance and can withstand elevated temperatures without losing their structural integrity. It is essential to choose a clamp coupling with a temperature rating that exceeds the operating temperature of the application to ensure safe and reliable performance.

In corrosive environments where exposure to chemicals, moisture, or other corrosive substances is a concern, selecting a corrosion-resistant material is critical. Stainless steel clamp couplings, particularly those made from 316-grade stainless steel, are widely used in such conditions due to their superior corrosion resistance. For more aggressive corrosive environments, special coatings or surface treatments can be applied to further enhance the coupling’s resistance to corrosion.

It is essential to consider the specific requirements of the application when selecting a clamp coupling for use in high-temperature or corrosive environments. Factors such as temperature, humidity, exposure to chemicals, and the presence of abrasive substances should be taken into account. Consulting with coupling manufacturers or industry experts can help in choosing the most suitable clamp coupling for the intended application.

Clamp Couplings and Damping Vibrations/Noise

Yes, clamp couplings can help dampen vibrations and reduce noise in mechanical systems to some extent. While not specifically designed as vibration isolators, clamp couplings can mitigate vibrations and noise due to their unique design and material properties.

The design of clamp couplings involves a split hub with screws that securely fasten around the shafts. This design offers several benefits:

- Damping Effect: The material of the coupling can absorb and dampen some of the vibrations generated by rotating equipment. Elastomeric elements or flexible materials used in some clamp couplings can help attenuate vibrations.

- Reduction of Resonance: Vibrations in rotating machinery can sometimes lead to resonance, causing excessive oscillations. Clamp couplings can help break the resonance cycle and prevent amplification of vibrations.

- Torsional Compliance: Some clamp couplings exhibit a degree of torsional compliance, which means they can tolerate small angular misalignments and dampen torsional vibrations.

- Transmissible Torque Variation: In some cases, clamp couplings can absorb torque spikes or variations, reducing the impact of sudden changes in load.

While clamp couplings can provide some level of vibration and noise reduction, their primary function is to transmit torque and accommodate misalignment between shafts. For more demanding vibration isolation or noise reduction applications, specialized components such as flexible couplings with damping features or dedicated vibration isolation mounts may be more suitable.

It is essential to consider the specific requirements of the mechanical system and consult with experts to determine the most appropriate coupling or isolator for achieving the desired level of vibration and noise reduction.

Different Types of Clamp Couplings

Clamp couplings come in various designs to accommodate different shaft sizes, torque levels, and application requirements. Some common types of clamp couplings available in the market include:

- Two-Piece Clamp Couplings: This type of coupling consists of two separate hubs that are connected by a clamp. The clamp is tightened to secure the two hubs onto the shafts, creating a rigid connection. Two-piece clamp couplings are easy to install and suitable for applications with moderate torque and misalignment.

- One-Piece Clamp Couplings: As the name suggests, one-piece clamp couplings have a single-piece construction, which simplifies the installation process. They provide a compact and lightweight solution for low to medium torque applications.

- Double-Walled Clamp Couplings: These couplings have a unique double-walled design, providing better torque transmission capabilities and torsional rigidity. They are ideal for applications with high torque and precise positioning requirements.

- Set Screw Clamp Couplings: Set screw clamp couplings use set screws to secure the coupling onto the shaft. While they are simple and cost-effective, they may not handle high torque and misalignment as effectively as other types.

- Wedge Clamp Couplings: Wedge clamp couplings use a wedge-shaped collar to create a tight grip on the shaft. They offer excellent torque transmission and axial holding power, making them suitable for heavy-duty applications.

- Keyless Clamp Couplings: Keyless clamp couplings eliminate the need for keyways and key connection. Instead, they use compression to secure the coupling to the shaft, providing high torque capacity and easy installation.

- Hydraulic Clamp Couplings: Hydraulic clamp couplings use hydraulic pressure to tighten the clamp, ensuring uniform pressure distribution and secure shaft connections. They are commonly used in high-power and critical applications.

- Clamp Couplings with Tapered Bushings: These couplings feature tapered bushings that provide a tight fit on the shaft and enhance torque transmission capabilities. They are suitable for heavy-duty applications and high misalignment conditions.

The selection of the appropriate clamp coupling depends on the specific requirements of the mechanical system, such as torque levels, shaft sizes, misalignment allowances, and operating conditions. Consulting with coupling manufacturers or engineering experts can help in choosing the right type of clamp coupling for a particular application.

editor by CX 2024-04-22