Product Description

Jingbang manufactures shaft collars in multiple styles to fit shafts ranging from 1/8″ to 6″ and 3mm to 150mm. They are made from select qualified bar stock in 303 & 316 stainless steel, black oxide and zinc plated carbon steel, high-strength aluminum, and engineered plastic. Our shaft collars have precisely controlled face to bore perpendicularity (identified by the grooved face) TIR ≤ .002″ (.05mm) with tighter tolerances on bearing locknuts. Perpendicularity is critical for alignment when a shaft collar is used as a load-bearing face, mechanical stop, or for mounting components. And we can also engrave the LOGO according to customer requirements

| Product Name | Shaft collar |

| Size | 1/8″ to 6″ and 3mm to 150mm. or non-standard according to your requirements. |

| Accept Material | AISI 303/304/316L, SUS 303/304/316, Aluminum 6061/6063/7075/2571, Brass/Bronze, Titanium etc. |

|

Accept Finish |

Machining, Plain, Polishing, Zinc- Plated, Black Oxide, Anodizing, Passivation, Galvanized nickel-alloy plated, Powder Coating, etc, as per your requirements. |

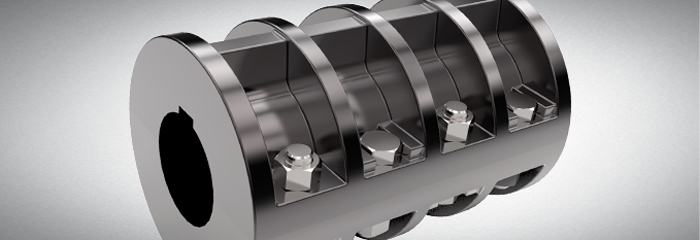

| Type | One-piece, Two-piece, Threaded, Shaft coupling, Heavy-duty, Mountable, Quick Clamping, Hex& D- Bore, Set screw |

| Standard | Metric, imperial |

| Packing Service | We generally packing fasteners to prevent them from colliding with each other during transportation to produce scratches and surface plating, also accept customization. |

| Sample Service | Free samples will be sent to you after confirming the order, and we will charge a sample fee for some products with high value. |

| We have stock of the following products, please contact us for the price! | ||

| ONE-PIECE: Carbon steel and black oxide

|

Bore size: 6mm,8mm,12mm,15mm, 16mm,18mm,20mm,22mm,25mm, 30mm,35mm,40mm,50mm,60mm, 70mm,75mm,80mm. |

|

| TWO-PIECES: Carbon steel and black oxide |

Bore size: 6mm,8mm,12mm,15mm, 16mm,18mm,20mm,22mm,25mm, 30mm,35mm,40mm,50mm,60mm, 70mm,75mm,80mm. |

|

| SET-SCREW: Carbon steel and black oxide |

Bore size:

8mm,10mm,13mm |

|

CUSTOM DESIGNS

As a service to our customers, we offer our vast manufacturing experience and talents to meet special needs with custom parts. Our in-house engineering team has extensive experience designing and custom engineering solutions to meet your requirements. If you do not see what you are looking for in our standard line, please inquire about custom options.

Materials & Finishs

Packaging & Shipping

We can also purchase and complete packaging according to customer requirements, such as blister boxes, rustproof paper, pearl cotton packaging, and we promise not to make a penny on extra packaging.

Production Process

Our Advantages

Company Profile

FAQ

| 1, How to ensure Shaft collar every process’s quality? |

| Every process will be checked by our quality inspection department which insures every product’s quality. In the production of products, we will personally go to the factory to check the quality of products. |

| 2, Shaft collar delivery time? |

| For Shaft collar we have stock, within 15 days; If customized, according to your quantity, about 20-25days. |

| 3, What is your payment method? |

| Paypal, Alibaba, 30% value of T/T in advance and other 70% balance before shipping. For small order less than1000USD, would suggest you pay 100% in advance to reduce the bank charges. |

| 4, Can you provide Shaft collar sample? |

| Sure, for stocked Shaft collar, we will provide free Shaft collar samples and you will be charged for shipping. |

How do Clamp Couplings Contribute to Reducing Backlash and Resonance in Rotating Machinery?

Clamp couplings play a crucial role in reducing backlash and resonance in rotating machinery, enhancing the overall performance and reliability of the system. Here’s how they achieve this:

1. Backlash Reduction:

Backlash is the play or clearance between mating components in a mechanical system. In rotating machinery, backlash can lead to lost motion, reduced precision, and inefficiencies. Clamp couplings offer several features that help minimize backlash:

- Zero-Backlash Design: Some clamp couplings are designed with a split hub and a clamping mechanism that ensures a tight fit around the shafts. This zero-backlash design eliminates any clearance between the coupling and the shafts, reducing or even eliminating backlash.

- High Clamping Force: Clamp couplings exert a strong clamping force on the shafts, ensuring a secure and rigid connection. This prevents any relative movement between the coupling and the shafts, further reducing backlash.

2. Resonance Damping:

Resonance occurs when the natural frequency of a rotating system matches the frequency of external forces or disturbances. This can lead to excessive vibrations and potential damage to the machinery. Clamp couplings can help dampen resonance in the following ways:

- Material Selection: High-quality materials like stainless steel or aluminum alloy are commonly used in clamp couplings. These materials possess excellent damping properties, dissipating vibrations and minimizing resonance effects.

- Precision Machining: Clamp couplings are precisely machined to maintain balance and reduce vibration during operation. Balanced couplings minimize the likelihood of resonant frequencies being excited, contributing to a smoother operation.

- Torsional Stiffness: Clamp couplings offer controlled torsional stiffness, which helps prevent the buildup of excessive vibration amplitudes and reduces resonance occurrences.

3. Misalignment Compensation:

Another factor contributing to backlash and resonance is misalignment between shafts. Clamp couplings can accommodate a certain degree of angular, parallel, and axial misalignments, reducing the impact of misalignment-induced backlash and vibrations.

Overall, clamp couplings provide a secure and precise connection between shafts, minimizing backlash and resonance in rotating machinery. By choosing the appropriate clamp coupling based on the specific requirements of the application, engineers can optimize the performance and efficiency of the rotating system.

Impact of Clamp Coupling Design on Performance in Heavy-Duty Applications

The design of a clamp coupling plays a crucial role in determining its performance, especially in heavy-duty applications. Here are some key design factors and their impact:

- Material Selection: The choice of material affects the strength, durability, and resistance to wear and corrosion. In heavy-duty applications, steel clamp couplings are often preferred due to their high tensile strength and ability to withstand heavy loads and torque.

- Torsional Rigidity: Heavy-duty applications often involve transmitting high levels of torque. A clamp coupling with higher torsional rigidity will maintain the connection between shafts more effectively, minimizing backlash and ensuring accurate power transmission.

- Hub Design: The hub of the clamp coupling should have a robust and precise design to provide a secure grip on the shafts. In heavy-duty applications, keyless and multiple screw designs are commonly used to distribute clamping forces evenly and prevent slippage.

- Number of Screws: The number of screws used to secure the clamp coupling to the shafts can impact its holding power. More screws distributed around the circumference can provide better balance and prevent distortion under heavy loads.

- Clamping Force: The clamping force applied by the coupling affects the torque transmission capabilities. In heavy-duty applications, it is crucial to ensure that the clamping force is sufficient to prevent slippage between the coupling and the shafts.

- Surface Treatment: The surface of the clamp coupling can be treated to enhance its resistance to corrosion, wear, and fatigue. Surface treatments like coating or plating can significantly improve the coupling’s performance and longevity in challenging environments.

- Alignment: Proper alignment during installation is vital to prevent premature wear and excessive stress on the coupling. In heavy-duty applications, precision alignment using alignment tools or laser systems is recommended to maintain optimal performance and prevent premature failure.

Conclusion: In heavy-duty applications, selecting a clamp coupling with the right material, torsional rigidity, hub design, number of screws, and clamping force is critical to ensuring reliable and efficient power transmission. Proper installation, regular maintenance, and adherence to manufacturer’s guidelines will further enhance the performance and longevity of the clamp coupling in heavy-duty applications.

Advantages of Using a Clamp Coupling

A clamp coupling offers several advantages compared to other types of couplings, making it a popular choice in various mechanical systems:

- Easy Installation: Clamp couplings are simple to install and require minimal tools and expertise. The design allows for quick assembly and disassembly, making maintenance and shaft replacement convenient.

- Cost-Effective: With a straightforward design and fewer components, clamp couplings are cost-effective to manufacture and purchase.

- High Torque Transmission: Clamp couplings can handle high torque loads, making them suitable for heavy-duty applications in industries like manufacturing, mining, and construction.

- Zero Backlash: The clamping mechanism ensures a tight fit between the shafts and the hubs, resulting in zero backlash. This feature is vital for applications that require accurate and precise motion transfer.

- Flexibility: Clamp couplings can accommodate different shaft sizes and materials, providing flexibility in system design and shaft compatibility.

- Compact Design: The compact and lightweight design of clamp couplings makes them ideal for applications with space constraints.

- No Lubrication Needed: Unlike some other couplings, clamp couplings do not require lubrication, reducing maintenance requirements and eliminating the risk of leakage or contamination in certain environments.

- High Misalignment Tolerance: Clamp couplings can handle moderate levels of angular, parallel, and axial misalignment, ensuring reliable operation even when shafts are not perfectly aligned.

- Reduced Downtime: The ease of installation and maintenance of clamp couplings contributes to reduced downtime during equipment repairs or replacements.

Due to these advantages, clamp couplings are widely used in various industries and mechanical setups for their simplicity, reliability, and cost-effectiveness in transmitting torque and rotational motion between shafts.

editor by CX 2023-10-12