Product Description

PVC GUTTER AND FITTINGS (BS EN607/12200/EN1462)

System: PVC Rain Gutter

Property: A rain gutter, eavestrough or surface water collection channel is a component of a water discharge system for a building.

Area: Mainly for American market,and African countries

Certificate: Kitemark Certificate,CE Certificate

Referenced Standards: BS EN607/12200/EN1462

Size: (BS) 5”(Square),7″(Square)

(DIN) 110,125,140MM,170MM,125MM(Square)

Description

Certificate

Related Products

Factory Introduction

Manufacturing plastic valves and fittings since 1993

ISO 9001- and ISO 14001-certified | 12 factories | Annual output of 500,000 tons

One of the Leading International Manufacturers of Plastic Valve and Fittings

ERA Co. Ltd has become 1 of the leading international manufacturers of plastic valve and fittings since its foundation in 1993. With an annual production capacity of 500,000 tons, we also have more than 4,000 employees in 12 factories covering 113,300 square meters in China, including 5 factories in HangZhou, and the other 7 ones in HangZhou, HangZhou, ZheJiang , ZheJiang , ZheJiang and ZheJiang .

Supported by Modern Equipment

We are equipped by 900 injection machines, 210extrusion machines and 10,000moulds, we have reach a sales turnover of $570million in 2016, including export sales of $55 million covering 224 countries worldwide.

Implementing Strict Quality Control

We strictly follow ISO 9001 quality system and ISO 14001 environment system to arrange manufacturing. With high-class raw material, strict quality control in both the workshop and laboratory with various professional testing equipment, we ensure that every single product meets the corresponding inspection standard.

FAQ

1.What is your MOQ?

Our MOQ is usually 5 CTNS.

2.What is your delievery time?

The time of delievery is around 30-45days.

3.What is the shipping port?

We ship the goods via HangZhou or ZheJiang port.

4.What is your payment terms?

We accept 30% T/T in advance,70% in the period of shipment or 100% L/C.

5.How should I contact you?

You can contact us with Trade Manager or send us an email by click Contact Supplier bottom.

6.What is the location of your company?

Our company is located in the HangZhou ZHangZhoug Province,China.

If you would like to have a visit, you are much welcome.

7.How about the samples?

We could send you the samples ,most samples are free to send to most places in China.If sent to other countries,transport fee shoule be paid by you.

8.Why choose us?

1 Genuine produces with excellent quality and competitive price.

2 Cooperating with the customers all over the world and knowing the markets very well.

3 CHINAMFG is a listed company. Everything can be rest assured working with us.

4 After- Services will be highly-satisfied. Any problems and feedbacks will be answered in a short of time. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

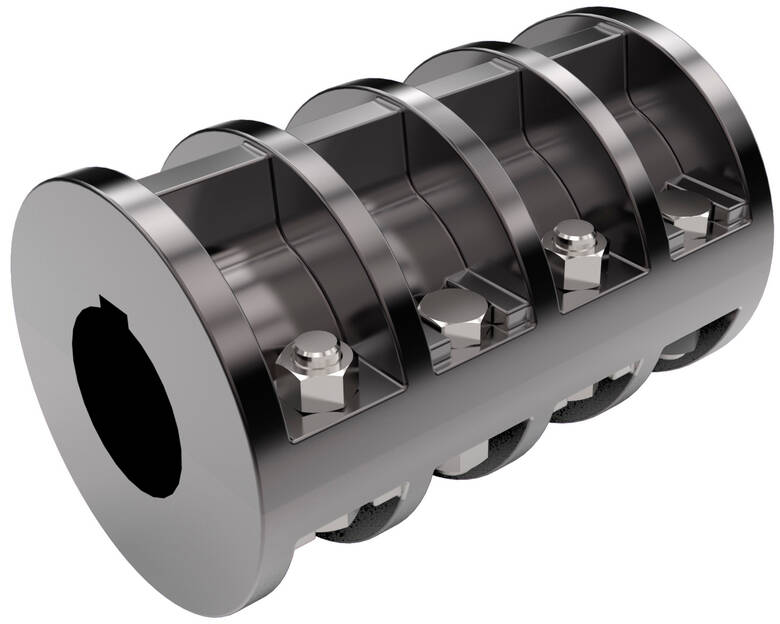

What Industries Commonly Use Clamp Couplings and Why?

Clamp couplings are widely used in various industries due to their versatility, ease of installation, and ability to accommodate different shaft sizes and misalignments. Some of the industries where clamp couplings are commonly used include:

- Manufacturing: In manufacturing industries, clamp couplings are commonly employed in conveyor systems, machine tools, and material handling equipment. They provide a reliable and flexible connection between shafts, allowing for smooth power transmission and easy maintenance.

- Agriculture: Farm machinery and equipment often use clamp couplings to connect power take-off shafts, ensuring efficient power transfer from the tractor to various implements like mowers, balers, and harvesters.

- Food and Beverage: The food and beverage industry requires couplings that are easy to clean and maintain. Stainless steel clamp couplings are commonly used in food processing equipment due to their corrosion resistance and hygienic design.

- Packaging: Packaging machinery often uses clamp couplings to connect rotating components, such as rollers and conveyors, ensuring precise and synchronized movement during the packaging process.

- Oil and Gas: In the oil and gas industry, clamp couplings are used in various applications, including pumps, compressors, and drilling equipment. Stainless steel clamp couplings are favored in offshore and corrosive environments.

- Automotive: In automotive manufacturing, clamp couplings find applications in power transmission systems, steering columns, and drivetrain components.

- Marine: The marine industry often employs clamp couplings in propulsion systems and auxiliary machinery, especially when corrosion resistance and reliability are critical.

- Pharmaceutical: Pharmaceutical manufacturing equipment requires couplings that meet stringent hygiene standards. Stainless steel clamp couplings are suitable for pharmaceutical applications due to their cleanability and resistance to contamination.

- Mining: Mining machinery relies on robust and reliable couplings to withstand heavy loads and harsh operating conditions. Clamp couplings are commonly used in conveyors, crushers, and other mining equipment.

The widespread use of clamp couplings across industries can be attributed to their ability to provide a secure and backlash-free connection between shafts, accommodate misalignment, and handle varying torque and speed requirements. Additionally, their simple design and ease of maintenance make them a popular choice in numerous industrial applications.

Differences between Clamp Couplings Made from Different Materials

Clamp couplings can be manufactured from various materials, each offering unique characteristics and suitability for different applications. Here are the main differences between clamp couplings made from aluminum, steel, and plastic:

- Aluminum Clamp Couplings: Aluminum clamp couplings are lightweight and offer excellent corrosion resistance. They are often used in applications where weight reduction is crucial, such as in aerospace and automotive industries. However, aluminum has lower tensile strength compared to steel, making it less suitable for heavy-duty or high-torque applications.

- Steel Clamp Couplings: Steel clamp couplings are known for their strength and durability. They can handle higher torque loads and are well-suited for heavy machinery, industrial equipment, and power transmission applications. Steel couplings are available in various grades, and surface treatments can further enhance their corrosion resistance.

- Plastic Clamp Couplings: Plastic clamp couplings are lightweight and cost-effective. They are commonly used in applications where weight is a concern, and the torque requirements are relatively low. Plastic couplings may offer good chemical resistance and electrical insulation properties, but they may not be as durable as metal couplings and are not suitable for high-load or high-temperature applications.

Considerations: When selecting a clamp coupling material, consider the specific requirements of your application:

- Load and Torque: Choose a material that can handle the expected load and torque of your application without exceeding the material’s limitations.

- Environment: Consider the operating environment, including exposure to chemicals, moisture, and temperature fluctuations, to ensure the chosen material can withstand these conditions.

- Cost and Weight: Balance the cost-effectiveness and weight-saving benefits of materials like aluminum and plastic against the strength and durability of steel.

Ultimately, the material selection for clamp couplings should be based on the specific demands of the application to ensure optimal performance and longevity.

Advantages of Using a Clamp Coupling

A clamp coupling offers several advantages compared to other types of couplings, making it a popular choice in various mechanical systems:

- Easy Installation: Clamp couplings are simple to install and require minimal tools and expertise. The design allows for quick assembly and disassembly, making maintenance and shaft replacement convenient.

- Cost-Effective: With a straightforward design and fewer components, clamp couplings are cost-effective to manufacture and purchase.

- High Torque Transmission: Clamp couplings can handle high torque loads, making them suitable for heavy-duty applications in industries like manufacturing, mining, and construction.

- Zero Backlash: The clamping mechanism ensures a tight fit between the shafts and the hubs, resulting in zero backlash. This feature is vital for applications that require accurate and precise motion transfer.

- Flexibility: Clamp couplings can accommodate different shaft sizes and materials, providing flexibility in system design and shaft compatibility.

- Compact Design: The compact and lightweight design of clamp couplings makes them ideal for applications with space constraints.

- No Lubrication Needed: Unlike some other couplings, clamp couplings do not require lubrication, reducing maintenance requirements and eliminating the risk of leakage or contamination in certain environments.

- High Misalignment Tolerance: Clamp couplings can handle moderate levels of angular, parallel, and axial misalignment, ensuring reliable operation even when shafts are not perfectly aligned.

- Reduced Downtime: The ease of installation and maintenance of clamp couplings contributes to reduced downtime during equipment repairs or replacements.

Due to these advantages, clamp couplings are widely used in various industries and mechanical setups for their simplicity, reliability, and cost-effectiveness in transmitting torque and rotational motion between shafts.

editor by CX 2024-04-11