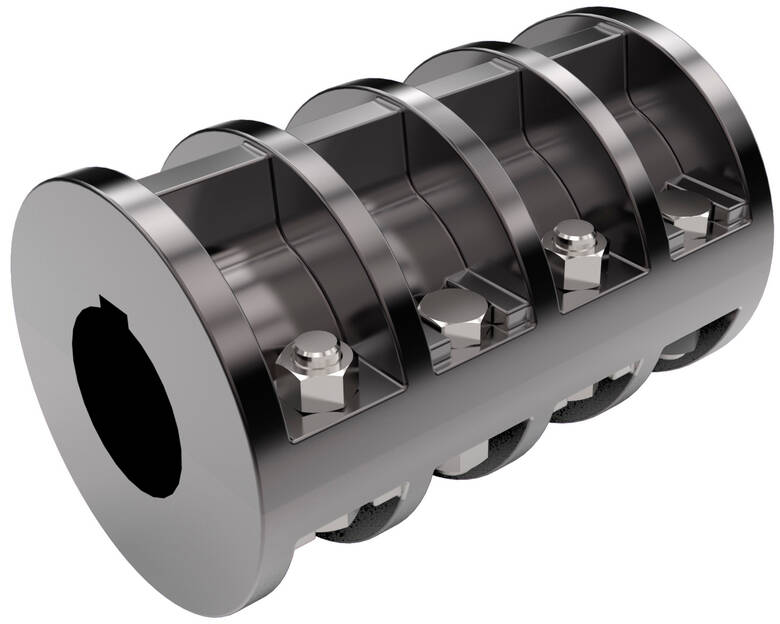

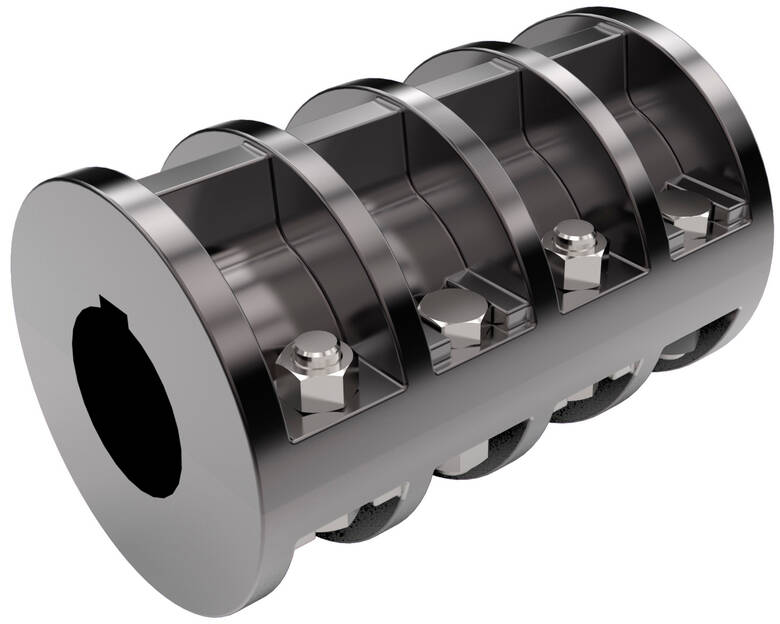

Product Description

Mechanical Coupling Shaft Elastomeric Stainless Steel Clamp Industrial Servo Flange Flexible Square Shaft Industrial Hydraulic Fluid Drive Roller Chain Spider

Product Description

-

Premium Quality: We use top-grade materials and advanced production techniques to ensure exceptional durability and load-bearing capacity.

-

Stringent Quality Control: Our bearings meet international standards with rigorous inspections at every stage, backed by ISO 9001 certification.

-

Comprehensive Product Range: We offer a wide variety of bearings including ball, roller, spherical, and custom-designed solutions for diverse applications.

-

Continuous Innovation: We stay ahead with cutting-edge technology, offering low-noise, high-speed, and long-life bearings.

-

Responsive Service: We promptly address customer inquiries, provide tailored design services, and ensure timely delivery.

-

Exceptional After-Sales Support: We stand behind our products with installation guidance, maintenance support, and reliable warranty coverage.

-

Competitive Pricing: By optimizing processes and economies of scale, we deliver cost-effective solutions without compromising on quality.

In essence, as your bearing supplier, we guarantee premium quality products, innovative solutions, responsive service, and strong value – making us the ideal partner for all your bearing needs.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the Torque and Speed Limits of Clamp Couplings in Various Applications?

The torque and speed limits of clamp couplings vary depending on their design, material, and application. Generally, clamp couplings are suitable for a wide range of torque and speed requirements in various mechanical systems. Here are some considerations:

Torque Limits:

Clamp couplings can handle a broad range of torque values, making them suitable for low, medium, and high torque applications. The torque capacity is influenced by factors such as the material and size of the coupling, as well as the clamping force applied to the shaft.

It is crucial to select a clamp coupling that can handle the maximum torque generated in the system during operation. Oversizing the coupling ensures it can safely transmit the required torque without reaching its limits, reducing the risk of premature failure.

Speed Limits:

Similar to torque limits, the speed limits of clamp couplings are influenced by their design and material. In high-speed applications, factors like centrifugal forces and resonance become significant considerations.

Clamp couplings made from high-strength materials like stainless steel or alloy steel can handle higher speeds with minimal risk of deformation or failure. Additionally, precision machining and balancing of the coupling help reduce vibration and maintain stability at elevated speeds.

Application-Specific Considerations:

When using clamp couplings in specific applications, factors like shock loads, reversing loads, and misalignment should be accounted for. These dynamic forces can impact the overall performance and durability of the coupling.

It is essential to consult the manufacturer’s specifications and guidelines for torque and speed ratings. Additionally, engineering calculations and simulations can help determine the most suitable clamp coupling for a particular application.

Professional Advice:

If you are unsure about the torque and speed limits of clamp couplings for your specific application, it is advisable to seek professional advice from coupling manufacturers or engineering experts. They can provide valuable insights and recommend the most appropriate coupling for your requirements, ensuring reliable and efficient power transmission in your mechanical system.

Impact of Clamp Coupling Design on Performance in Heavy-Duty Applications

The design of a clamp coupling plays a crucial role in determining its performance, especially in heavy-duty applications. Here are some key design factors and their impact:

- Material Selection: The choice of material affects the strength, durability, and resistance to wear and corrosion. In heavy-duty applications, steel clamp couplings are often preferred due to their high tensile strength and ability to withstand heavy loads and torque.

- Torsional Rigidity: Heavy-duty applications often involve transmitting high levels of torque. A clamp coupling with higher torsional rigidity will maintain the connection between shafts more effectively, minimizing backlash and ensuring accurate power transmission.

- Hub Design: The hub of the clamp coupling should have a robust and precise design to provide a secure grip on the shafts. In heavy-duty applications, keyless and multiple screw designs are commonly used to distribute clamping forces evenly and prevent slippage.

- Number of Screws: The number of screws used to secure the clamp coupling to the shafts can impact its holding power. More screws distributed around the circumference can provide better balance and prevent distortion under heavy loads.

- Clamping Force: The clamping force applied by the coupling affects the torque transmission capabilities. In heavy-duty applications, it is crucial to ensure that the clamping force is sufficient to prevent slippage between the coupling and the shafts.

- Surface Treatment: The surface of the clamp coupling can be treated to enhance its resistance to corrosion, wear, and fatigue. Surface treatments like coating or plating can significantly improve the coupling’s performance and longevity in challenging environments.

- Alignment: Proper alignment during installation is vital to prevent premature wear and excessive stress on the coupling. In heavy-duty applications, precision alignment using alignment tools or laser systems is recommended to maintain optimal performance and prevent premature failure.

Conclusion: In heavy-duty applications, selecting a clamp coupling with the right material, torsional rigidity, hub design, number of screws, and clamping force is critical to ensuring reliable and efficient power transmission. Proper installation, regular maintenance, and adherence to manufacturer’s guidelines will further enhance the performance and longevity of the clamp coupling in heavy-duty applications.

Handling Misalignment with Clamp Couplings

Yes, clamp couplings are designed to handle certain degrees of misalignment between shafts effectively. They can accommodate both angular and parallel misalignments, making them versatile for various mechanical systems.

The design of clamp couplings allows for a certain degree of flexibility and forgiveness in the coupling’s connection. When the shafts are not perfectly aligned due to angular or parallel misalignment, the clamp coupling can compensate for these variations.

The main factors contributing to the clamp coupling’s ability to handle misalignment are:

- Flexible Material: Clamp couplings are often made of materials like aluminum, stainless steel, or other alloys with some elasticity. This flexibility enables them to absorb and compensate for minor misalignments.

- Split Design: Clamp couplings usually have a split design with one or more screws or bolts that can be tightened to secure the coupling around the shafts. This design allows for easy installation and adjustment, making it possible to accommodate slight misalignments during assembly.

- Tightening Mechanism: The screws or bolts used to fasten the clamp coupling can be tightened to the appropriate torque, providing a secure connection while still allowing for a certain amount of movement to handle misalignment.

However, it’s important to note that clamp couplings have limitations when it comes to misalignment. Excessive misalignment can lead to increased wear on the coupling components and shafts, reducing the coupling’s lifespan and potentially causing failure. Therefore, it’s essential to ensure that the misalignment does not exceed the coupling’s specified limits.

For more significant misalignments or applications with constant large misalignments, flexible couplings like elastomeric couplings or gear couplings may be more suitable. It’s crucial to select the appropriate coupling type based on the specific misalignment requirements of the mechanical system.

In conclusion, while clamp couplings can handle certain degrees of misalignment effectively, it is essential to stay within the recommended misalignment limits to maintain the coupling’s performance and longevity.

editor by CX 2024-05-13

China Custom Mechanical Coupling Shaft Elastomeric Stainless Steel Clamp Industrial Servo Flange Flexible Square Shaft Industrial Hydraulic Fluid Drive Roller Chain Spider

Product Description

Mechanical Coupling Shaft Elastomeric Stainless Steel Clamp Industrial Servo Flange Flexible Square Shaft Industrial Hydraulic Fluid Drive Roller Chain Spider

Product Description

-

Premium Quality: We use top-grade materials and advanced production techniques to ensure exceptional durability and load-bearing capacity.

-

Stringent Quality Control: Our bearings meet international standards with rigorous inspections at every stage, backed by ISO 9001 certification.

-

Comprehensive Product Range: We offer a wide variety of bearings including ball, roller, spherical, and custom-designed solutions for diverse applications.

-

Continuous Innovation: We stay ahead with cutting-edge technology, offering low-noise, high-speed, and long-life bearings.

-

Responsive Service: We promptly address customer inquiries, provide tailored design services, and ensure timely delivery.

-

Exceptional After-Sales Support: We stand behind our products with installation guidance, maintenance support, and reliable warranty coverage.

-

Competitive Pricing: By optimizing processes and economies of scale, we deliver cost-effective solutions without compromising on quality.

In essence, as your bearing supplier, we guarantee premium quality products, innovative solutions, responsive service, and strong value – making us the ideal partner for all your bearing needs.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the Torque and Speed Limits of Clamp Couplings in Various Applications?

The torque and speed limits of clamp couplings vary depending on their design, material, and application. Generally, clamp couplings are suitable for a wide range of torque and speed requirements in various mechanical systems. Here are some considerations:

Torque Limits:

Clamp couplings can handle a broad range of torque values, making them suitable for low, medium, and high torque applications. The torque capacity is influenced by factors such as the material and size of the coupling, as well as the clamping force applied to the shaft.

It is crucial to select a clamp coupling that can handle the maximum torque generated in the system during operation. Oversizing the coupling ensures it can safely transmit the required torque without reaching its limits, reducing the risk of premature failure.

Speed Limits:

Similar to torque limits, the speed limits of clamp couplings are influenced by their design and material. In high-speed applications, factors like centrifugal forces and resonance become significant considerations.

Clamp couplings made from high-strength materials like stainless steel or alloy steel can handle higher speeds with minimal risk of deformation or failure. Additionally, precision machining and balancing of the coupling help reduce vibration and maintain stability at elevated speeds.

Application-Specific Considerations:

When using clamp couplings in specific applications, factors like shock loads, reversing loads, and misalignment should be accounted for. These dynamic forces can impact the overall performance and durability of the coupling.

It is essential to consult the manufacturer’s specifications and guidelines for torque and speed ratings. Additionally, engineering calculations and simulations can help determine the most suitable clamp coupling for a particular application.

Professional Advice:

If you are unsure about the torque and speed limits of clamp couplings for your specific application, it is advisable to seek professional advice from coupling manufacturers or engineering experts. They can provide valuable insights and recommend the most appropriate coupling for your requirements, ensuring reliable and efficient power transmission in your mechanical system.

Real-World Case Studies of Clamp Couplings in Engineering Projects

Clamp couplings have been widely used in various engineering projects, showcasing their effectiveness and reliability. Here are some real-world case studies:

- Wind Turbine Applications: In the renewable energy sector, wind turbines require efficient power transmission between the rotor and generator. Clamp couplings have been successfully used to connect the shafts, allowing for easy installation, alignment, and maintenance. Their ability to handle high torque and misalignment ensures reliable performance even in harsh environmental conditions.

- Industrial Machinery: In heavy machinery and industrial equipment, clamp couplings have proven to be a preferred choice for connecting rotating shafts. A case study involving a large-scale conveyor system in a mining operation demonstrated that clamp couplings provided excellent torque transmission and allowed for quick and straightforward replacement during maintenance.

- Marine Propulsion Systems: Clamp couplings are widely used in marine propulsion systems for boats and ships. A case study involving a commercial vessel showed that stainless steel clamp couplings significantly reduced maintenance downtime due to their corrosion resistance and ability to handle dynamic loads, ensuring smooth and reliable operation.

- Aerospace Applications: In the aerospace industry, clamp couplings have been employed in critical components such as flight control systems and engine assemblies. A case study involving an aircraft engine demonstrated that clamp couplings provided precise and robust shaft connections, contributing to the overall performance and safety of the aircraft.

- Automotive Engineering: In automotive engineering, clamp couplings are used in various drivetrain components. A case study involving an electric vehicle showcased that clamp couplings allowed for compact and lightweight designs, minimizing power losses and enhancing energy efficiency.

Conclusion: These case studies highlight the versatility and reliability of clamp couplings in diverse engineering projects. Whether in renewable energy, heavy machinery, marine, aerospace, or automotive applications, clamp couplings have proven to be an effective solution for connecting rotating shafts, providing efficient power transmission, and reducing maintenance downtime.

Advantages of Using a Clamp Coupling

A clamp coupling offers several advantages compared to other types of couplings, making it a popular choice in various mechanical systems:

- Easy Installation: Clamp couplings are simple to install and require minimal tools and expertise. The design allows for quick assembly and disassembly, making maintenance and shaft replacement convenient.

- Cost-Effective: With a straightforward design and fewer components, clamp couplings are cost-effective to manufacture and purchase.

- High Torque Transmission: Clamp couplings can handle high torque loads, making them suitable for heavy-duty applications in industries like manufacturing, mining, and construction.

- Zero Backlash: The clamping mechanism ensures a tight fit between the shafts and the hubs, resulting in zero backlash. This feature is vital for applications that require accurate and precise motion transfer.

- Flexibility: Clamp couplings can accommodate different shaft sizes and materials, providing flexibility in system design and shaft compatibility.

- Compact Design: The compact and lightweight design of clamp couplings makes them ideal for applications with space constraints.

- No Lubrication Needed: Unlike some other couplings, clamp couplings do not require lubrication, reducing maintenance requirements and eliminating the risk of leakage or contamination in certain environments.

- High Misalignment Tolerance: Clamp couplings can handle moderate levels of angular, parallel, and axial misalignment, ensuring reliable operation even when shafts are not perfectly aligned.

- Reduced Downtime: The ease of installation and maintenance of clamp couplings contributes to reduced downtime during equipment repairs or replacements.

Due to these advantages, clamp couplings are widely used in various industries and mechanical setups for their simplicity, reliability, and cost-effectiveness in transmitting torque and rotational motion between shafts.

editor by CX 2024-05-07

B made in China – replacement parts – in Louisville United States Series Stainless Steel Driving Chains Short Pitch Precision Single Roller Chain Ss04b1 05b1 06b1 08b1 10b1 12b1 16b1 20b1 with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

B Series Stainless Steel Driving Chains Short Pitch Precision Single Roller Chain Ss04b1 05b1 06b1 08b1 10b1 12b1 16b1 20b1

1. Product name : Industrial Roller Chains

2. Size: Ss04b1 05b1 06b1 08b1 10b1 12b1 16b1 20b1

3. Standard: DIN /ISO

4. Certification: ISO9001

|

Product Name |

Ready for shipment in warehous Duplex Roller Chains 16B-6 |

|

Material |

40Mn plate |

|

color |

shot bla EPT surface treatment |

|

Standard |

DIN ISO |

|

Grade |

Standard |

|

Brand |

UIB |

|

Pitch |

25.4mm |

|

Used |

universal industry machinery |

The use of original equipment manufacturer’s (OEM) part numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the listed replacement parts contained herein are not sponsored, approved, or manufactured by the OEM.

Stainless made in China – replacement parts – in Joinville Brazil Steel Roller Chain Alloy Steel Conveyor Chain with Pins with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

| EPT chain | 78PF1 conveyor chains |

We supply good quality 78PF1 conveyor chains,all the kinds which you need, any demand p EPT contact us!

The use of original equipment manufacturer’s (OEM) part numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the listed replacement parts contained herein are not sponsored, approved, or manufactured by the OEM.