Product Description

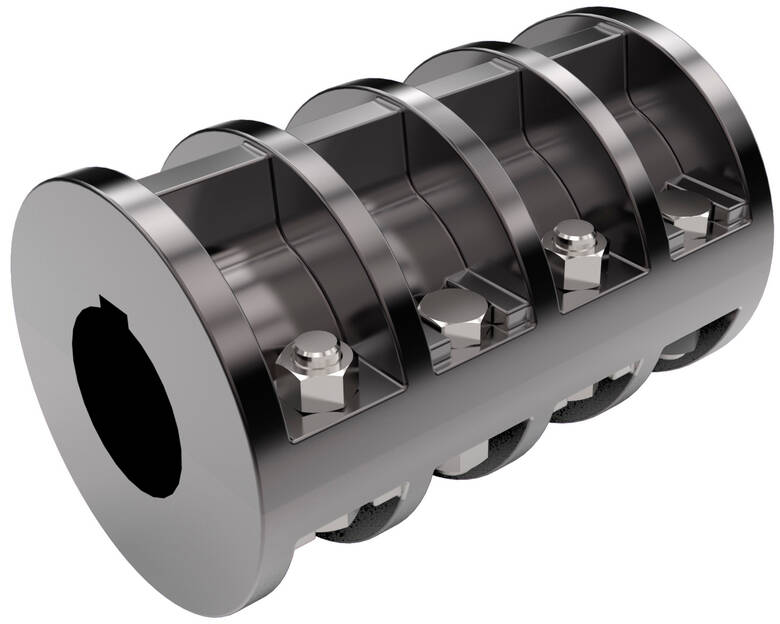

Mechanical Coupling Shaft Elastomeric Stainless Steel Clamp Industrial Servo Flange Flexible Square Shaft Industrial Hydraulic Fluid Drive Roller Chain Spider

Product Description

-

Premium Quality: We use top-grade materials and advanced production techniques to ensure exceptional durability and load-bearing capacity.

-

Stringent Quality Control: Our bearings meet international standards with rigorous inspections at every stage, backed by ISO 9001 certification.

-

Comprehensive Product Range: We offer a wide variety of bearings including ball, roller, spherical, and custom-designed solutions for diverse applications.

-

Continuous Innovation: We stay ahead with cutting-edge technology, offering low-noise, high-speed, and long-life bearings.

-

Responsive Service: We promptly address customer inquiries, provide tailored design services, and ensure timely delivery.

-

Exceptional After-Sales Support: We stand behind our products with installation guidance, maintenance support, and reliable warranty coverage.

-

Competitive Pricing: By optimizing processes and economies of scale, we deliver cost-effective solutions without compromising on quality.

In essence, as your bearing supplier, we guarantee premium quality products, innovative solutions, responsive service, and strong value – making us the ideal partner for all your bearing needs.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the Torque and Speed Limits of Clamp Couplings in Various Applications?

The torque and speed limits of clamp couplings vary depending on their design, material, and application. Generally, clamp couplings are suitable for a wide range of torque and speed requirements in various mechanical systems. Here are some considerations:

Torque Limits:

Clamp couplings can handle a broad range of torque values, making them suitable for low, medium, and high torque applications. The torque capacity is influenced by factors such as the material and size of the coupling, as well as the clamping force applied to the shaft.

It is crucial to select a clamp coupling that can handle the maximum torque generated in the system during operation. Oversizing the coupling ensures it can safely transmit the required torque without reaching its limits, reducing the risk of premature failure.

Speed Limits:

Similar to torque limits, the speed limits of clamp couplings are influenced by their design and material. In high-speed applications, factors like centrifugal forces and resonance become significant considerations.

Clamp couplings made from high-strength materials like stainless steel or alloy steel can handle higher speeds with minimal risk of deformation or failure. Additionally, precision machining and balancing of the coupling help reduce vibration and maintain stability at elevated speeds.

Application-Specific Considerations:

When using clamp couplings in specific applications, factors like shock loads, reversing loads, and misalignment should be accounted for. These dynamic forces can impact the overall performance and durability of the coupling.

It is essential to consult the manufacturer’s specifications and guidelines for torque and speed ratings. Additionally, engineering calculations and simulations can help determine the most suitable clamp coupling for a particular application.

Professional Advice:

If you are unsure about the torque and speed limits of clamp couplings for your specific application, it is advisable to seek professional advice from coupling manufacturers or engineering experts. They can provide valuable insights and recommend the most appropriate coupling for your requirements, ensuring reliable and efficient power transmission in your mechanical system.

Impact of Clamp Coupling Design on Performance in Heavy-Duty Applications

The design of a clamp coupling plays a crucial role in determining its performance, especially in heavy-duty applications. Here are some key design factors and their impact:

- Material Selection: The choice of material affects the strength, durability, and resistance to wear and corrosion. In heavy-duty applications, steel clamp couplings are often preferred due to their high tensile strength and ability to withstand heavy loads and torque.

- Torsional Rigidity: Heavy-duty applications often involve transmitting high levels of torque. A clamp coupling with higher torsional rigidity will maintain the connection between shafts more effectively, minimizing backlash and ensuring accurate power transmission.

- Hub Design: The hub of the clamp coupling should have a robust and precise design to provide a secure grip on the shafts. In heavy-duty applications, keyless and multiple screw designs are commonly used to distribute clamping forces evenly and prevent slippage.

- Number of Screws: The number of screws used to secure the clamp coupling to the shafts can impact its holding power. More screws distributed around the circumference can provide better balance and prevent distortion under heavy loads.

- Clamping Force: The clamping force applied by the coupling affects the torque transmission capabilities. In heavy-duty applications, it is crucial to ensure that the clamping force is sufficient to prevent slippage between the coupling and the shafts.

- Surface Treatment: The surface of the clamp coupling can be treated to enhance its resistance to corrosion, wear, and fatigue. Surface treatments like coating or plating can significantly improve the coupling’s performance and longevity in challenging environments.

- Alignment: Proper alignment during installation is vital to prevent premature wear and excessive stress on the coupling. In heavy-duty applications, precision alignment using alignment tools or laser systems is recommended to maintain optimal performance and prevent premature failure.

Conclusion: In heavy-duty applications, selecting a clamp coupling with the right material, torsional rigidity, hub design, number of screws, and clamping force is critical to ensuring reliable and efficient power transmission. Proper installation, regular maintenance, and adherence to manufacturer’s guidelines will further enhance the performance and longevity of the clamp coupling in heavy-duty applications.

Handling Misalignment with Clamp Couplings

Yes, clamp couplings are designed to handle certain degrees of misalignment between shafts effectively. They can accommodate both angular and parallel misalignments, making them versatile for various mechanical systems.

The design of clamp couplings allows for a certain degree of flexibility and forgiveness in the coupling’s connection. When the shafts are not perfectly aligned due to angular or parallel misalignment, the clamp coupling can compensate for these variations.

The main factors contributing to the clamp coupling’s ability to handle misalignment are:

- Flexible Material: Clamp couplings are often made of materials like aluminum, stainless steel, or other alloys with some elasticity. This flexibility enables them to absorb and compensate for minor misalignments.

- Split Design: Clamp couplings usually have a split design with one or more screws or bolts that can be tightened to secure the coupling around the shafts. This design allows for easy installation and adjustment, making it possible to accommodate slight misalignments during assembly.

- Tightening Mechanism: The screws or bolts used to fasten the clamp coupling can be tightened to the appropriate torque, providing a secure connection while still allowing for a certain amount of movement to handle misalignment.

However, it’s important to note that clamp couplings have limitations when it comes to misalignment. Excessive misalignment can lead to increased wear on the coupling components and shafts, reducing the coupling’s lifespan and potentially causing failure. Therefore, it’s essential to ensure that the misalignment does not exceed the coupling’s specified limits.

For more significant misalignments or applications with constant large misalignments, flexible couplings like elastomeric couplings or gear couplings may be more suitable. It’s crucial to select the appropriate coupling type based on the specific misalignment requirements of the mechanical system.

In conclusion, while clamp couplings can handle certain degrees of misalignment effectively, it is essential to stay within the recommended misalignment limits to maintain the coupling’s performance and longevity.

editor by CX 2024-05-13

China Custom Mechanical Coupling Shaft Elastomeric Stainless Steel Clamp Industrial Servo Flange Flexible Square Shaft Industrial Hydraulic Fluid Drive Roller Chain Spider

Product Description

Mechanical Coupling Shaft Elastomeric Stainless Steel Clamp Industrial Servo Flange Flexible Square Shaft Industrial Hydraulic Fluid Drive Roller Chain Spider

Product Description

-

Premium Quality: We use top-grade materials and advanced production techniques to ensure exceptional durability and load-bearing capacity.

-

Stringent Quality Control: Our bearings meet international standards with rigorous inspections at every stage, backed by ISO 9001 certification.

-

Comprehensive Product Range: We offer a wide variety of bearings including ball, roller, spherical, and custom-designed solutions for diverse applications.

-

Continuous Innovation: We stay ahead with cutting-edge technology, offering low-noise, high-speed, and long-life bearings.

-

Responsive Service: We promptly address customer inquiries, provide tailored design services, and ensure timely delivery.

-

Exceptional After-Sales Support: We stand behind our products with installation guidance, maintenance support, and reliable warranty coverage.

-

Competitive Pricing: By optimizing processes and economies of scale, we deliver cost-effective solutions without compromising on quality.

In essence, as your bearing supplier, we guarantee premium quality products, innovative solutions, responsive service, and strong value – making us the ideal partner for all your bearing needs.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the Torque and Speed Limits of Clamp Couplings in Various Applications?

The torque and speed limits of clamp couplings vary depending on their design, material, and application. Generally, clamp couplings are suitable for a wide range of torque and speed requirements in various mechanical systems. Here are some considerations:

Torque Limits:

Clamp couplings can handle a broad range of torque values, making them suitable for low, medium, and high torque applications. The torque capacity is influenced by factors such as the material and size of the coupling, as well as the clamping force applied to the shaft.

It is crucial to select a clamp coupling that can handle the maximum torque generated in the system during operation. Oversizing the coupling ensures it can safely transmit the required torque without reaching its limits, reducing the risk of premature failure.

Speed Limits:

Similar to torque limits, the speed limits of clamp couplings are influenced by their design and material. In high-speed applications, factors like centrifugal forces and resonance become significant considerations.

Clamp couplings made from high-strength materials like stainless steel or alloy steel can handle higher speeds with minimal risk of deformation or failure. Additionally, precision machining and balancing of the coupling help reduce vibration and maintain stability at elevated speeds.

Application-Specific Considerations:

When using clamp couplings in specific applications, factors like shock loads, reversing loads, and misalignment should be accounted for. These dynamic forces can impact the overall performance and durability of the coupling.

It is essential to consult the manufacturer’s specifications and guidelines for torque and speed ratings. Additionally, engineering calculations and simulations can help determine the most suitable clamp coupling for a particular application.

Professional Advice:

If you are unsure about the torque and speed limits of clamp couplings for your specific application, it is advisable to seek professional advice from coupling manufacturers or engineering experts. They can provide valuable insights and recommend the most appropriate coupling for your requirements, ensuring reliable and efficient power transmission in your mechanical system.

Real-World Case Studies of Clamp Couplings in Engineering Projects

Clamp couplings have been widely used in various engineering projects, showcasing their effectiveness and reliability. Here are some real-world case studies:

- Wind Turbine Applications: In the renewable energy sector, wind turbines require efficient power transmission between the rotor and generator. Clamp couplings have been successfully used to connect the shafts, allowing for easy installation, alignment, and maintenance. Their ability to handle high torque and misalignment ensures reliable performance even in harsh environmental conditions.

- Industrial Machinery: In heavy machinery and industrial equipment, clamp couplings have proven to be a preferred choice for connecting rotating shafts. A case study involving a large-scale conveyor system in a mining operation demonstrated that clamp couplings provided excellent torque transmission and allowed for quick and straightforward replacement during maintenance.

- Marine Propulsion Systems: Clamp couplings are widely used in marine propulsion systems for boats and ships. A case study involving a commercial vessel showed that stainless steel clamp couplings significantly reduced maintenance downtime due to their corrosion resistance and ability to handle dynamic loads, ensuring smooth and reliable operation.

- Aerospace Applications: In the aerospace industry, clamp couplings have been employed in critical components such as flight control systems and engine assemblies. A case study involving an aircraft engine demonstrated that clamp couplings provided precise and robust shaft connections, contributing to the overall performance and safety of the aircraft.

- Automotive Engineering: In automotive engineering, clamp couplings are used in various drivetrain components. A case study involving an electric vehicle showcased that clamp couplings allowed for compact and lightweight designs, minimizing power losses and enhancing energy efficiency.

Conclusion: These case studies highlight the versatility and reliability of clamp couplings in diverse engineering projects. Whether in renewable energy, heavy machinery, marine, aerospace, or automotive applications, clamp couplings have proven to be an effective solution for connecting rotating shafts, providing efficient power transmission, and reducing maintenance downtime.

Advantages of Using a Clamp Coupling

A clamp coupling offers several advantages compared to other types of couplings, making it a popular choice in various mechanical systems:

- Easy Installation: Clamp couplings are simple to install and require minimal tools and expertise. The design allows for quick assembly and disassembly, making maintenance and shaft replacement convenient.

- Cost-Effective: With a straightforward design and fewer components, clamp couplings are cost-effective to manufacture and purchase.

- High Torque Transmission: Clamp couplings can handle high torque loads, making them suitable for heavy-duty applications in industries like manufacturing, mining, and construction.

- Zero Backlash: The clamping mechanism ensures a tight fit between the shafts and the hubs, resulting in zero backlash. This feature is vital for applications that require accurate and precise motion transfer.

- Flexibility: Clamp couplings can accommodate different shaft sizes and materials, providing flexibility in system design and shaft compatibility.

- Compact Design: The compact and lightweight design of clamp couplings makes them ideal for applications with space constraints.

- No Lubrication Needed: Unlike some other couplings, clamp couplings do not require lubrication, reducing maintenance requirements and eliminating the risk of leakage or contamination in certain environments.

- High Misalignment Tolerance: Clamp couplings can handle moderate levels of angular, parallel, and axial misalignment, ensuring reliable operation even when shafts are not perfectly aligned.

- Reduced Downtime: The ease of installation and maintenance of clamp couplings contributes to reduced downtime during equipment repairs or replacements.

Due to these advantages, clamp couplings are widely used in various industries and mechanical setups for their simplicity, reliability, and cost-effectiveness in transmitting torque and rotational motion between shafts.

editor by CX 2024-05-07

China Professional Auto Parts Flexible Clamping Aluminum Alloy Stainless Steel Shaft Coupling Multi Size

Product Description

|

Product Name |

Auto Parts Flexible Clamping Aluminum Alloy Stainless Steel Shaft Coupling Multi Size |

|

Material |

Aluminum alloy |

|

Surface treatment |

Natural color anode |

|

Customized service |

Support light customization and logo customization |

|

Remarks |

The default engraving brand name and size of the product. If you need not engraving, please contact the customer service for comments |

| Packaging Details | Carton box with anti-static package,carton plus with wooden case. |

| Main Products | Shaft Parts, Timing Belt Pulley, Gears, CNC Machining Parts, Sheet Metal Fabrication |

| Certifications(2) | ISO9001:2015, IPMS |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Food & Beverage Factory, Farms |

| Supply Ability | 100000 Piece/Pieces per Month |

| Dimension | oem provided |

| Surface finish | anodized |

| Lead Time | 25 days |

| Application | Furniture,cabinet |

| Custom | OEM and ODM services are welcome,we can make cutom LOGO and products according to customer’s requests. |

| Quality control Our | Finished product inspection,Warranty available |

| service | Swiss machining;deburring;lathe/turning;5 axis;micromachining |

| Color |

silver,gold,black,red,bulue,and according to the customer requests. |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the Torque and Speed Limits of Clamp Couplings in Various Applications?

The torque and speed limits of clamp couplings vary depending on their design, material, and application. Generally, clamp couplings are suitable for a wide range of torque and speed requirements in various mechanical systems. Here are some considerations:

Torque Limits:

Clamp couplings can handle a broad range of torque values, making them suitable for low, medium, and high torque applications. The torque capacity is influenced by factors such as the material and size of the coupling, as well as the clamping force applied to the shaft.

It is crucial to select a clamp coupling that can handle the maximum torque generated in the system during operation. Oversizing the coupling ensures it can safely transmit the required torque without reaching its limits, reducing the risk of premature failure.

Speed Limits:

Similar to torque limits, the speed limits of clamp couplings are influenced by their design and material. In high-speed applications, factors like centrifugal forces and resonance become significant considerations.

Clamp couplings made from high-strength materials like stainless steel or alloy steel can handle higher speeds with minimal risk of deformation or failure. Additionally, precision machining and balancing of the coupling help reduce vibration and maintain stability at elevated speeds.

Application-Specific Considerations:

When using clamp couplings in specific applications, factors like shock loads, reversing loads, and misalignment should be accounted for. These dynamic forces can impact the overall performance and durability of the coupling.

It is essential to consult the manufacturer’s specifications and guidelines for torque and speed ratings. Additionally, engineering calculations and simulations can help determine the most suitable clamp coupling for a particular application.

Professional Advice:

If you are unsure about the torque and speed limits of clamp couplings for your specific application, it is advisable to seek professional advice from coupling manufacturers or engineering experts. They can provide valuable insights and recommend the most appropriate coupling for your requirements, ensuring reliable and efficient power transmission in your mechanical system.

Real-World Case Studies of Clamp Couplings in Engineering Projects

Clamp couplings have been widely used in various engineering projects, showcasing their effectiveness and reliability. Here are some real-world case studies:

- Wind Turbine Applications: In the renewable energy sector, wind turbines require efficient power transmission between the rotor and generator. Clamp couplings have been successfully used to connect the shafts, allowing for easy installation, alignment, and maintenance. Their ability to handle high torque and misalignment ensures reliable performance even in harsh environmental conditions.

- Industrial Machinery: In heavy machinery and industrial equipment, clamp couplings have proven to be a preferred choice for connecting rotating shafts. A case study involving a large-scale conveyor system in a mining operation demonstrated that clamp couplings provided excellent torque transmission and allowed for quick and straightforward replacement during maintenance.

- Marine Propulsion Systems: Clamp couplings are widely used in marine propulsion systems for boats and ships. A case study involving a commercial vessel showed that stainless steel clamp couplings significantly reduced maintenance downtime due to their corrosion resistance and ability to handle dynamic loads, ensuring smooth and reliable operation.

- Aerospace Applications: In the aerospace industry, clamp couplings have been employed in critical components such as flight control systems and engine assemblies. A case study involving an aircraft engine demonstrated that clamp couplings provided precise and robust shaft connections, contributing to the overall performance and safety of the aircraft.

- Automotive Engineering: In automotive engineering, clamp couplings are used in various drivetrain components. A case study involving an electric vehicle showcased that clamp couplings allowed for compact and lightweight designs, minimizing power losses and enhancing energy efficiency.

Conclusion: These case studies highlight the versatility and reliability of clamp couplings in diverse engineering projects. Whether in renewable energy, heavy machinery, marine, aerospace, or automotive applications, clamp couplings have proven to be an effective solution for connecting rotating shafts, providing efficient power transmission, and reducing maintenance downtime.

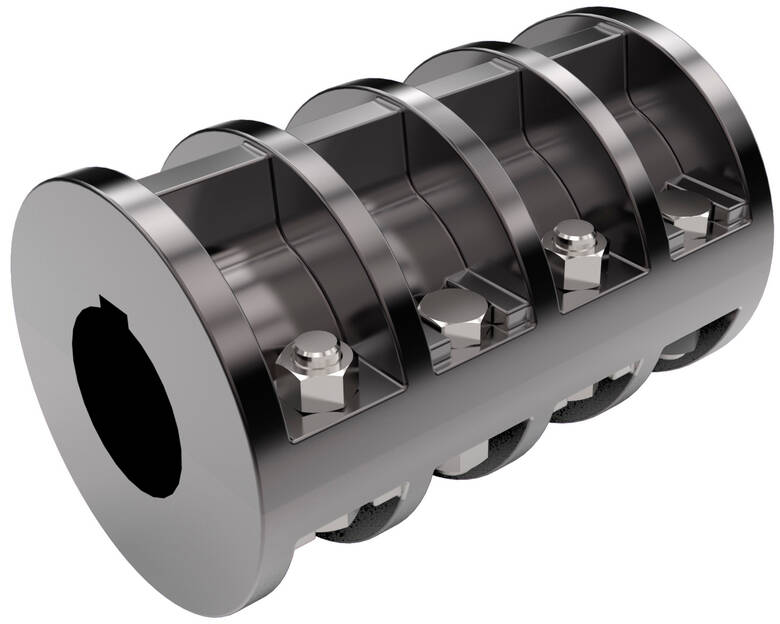

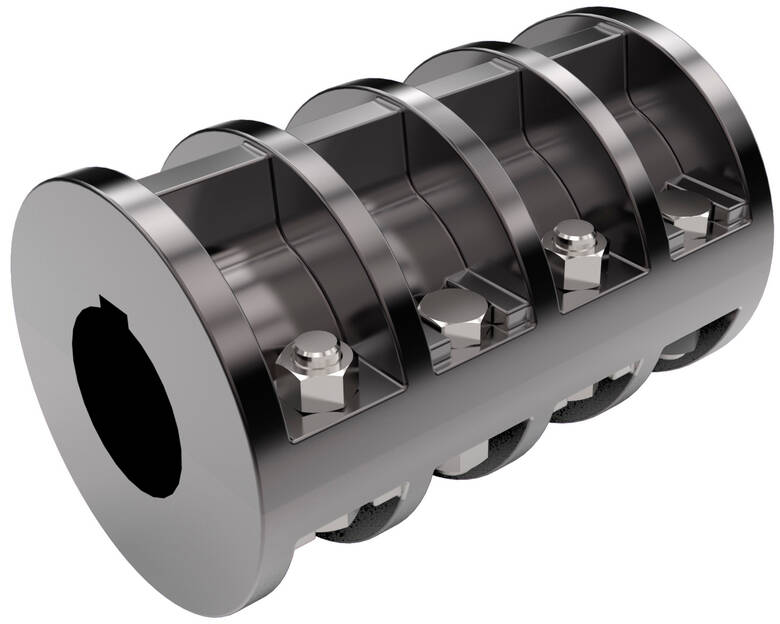

What is a Clamp Coupling and How Does it Work?

A clamp coupling is a type of mechanical coupling used to connect two shafts together to transmit torque and rotational motion between them. It is a simple and effective way of joining shafts in various mechanical systems. The main components of a clamp coupling typically include two hubs and a center section.

Working Principle:

The clamp coupling works on the principle of frictional force and mechanical interference fit. Here’s how it functions:

- Hub Assembly: Each end of the shaft has a hub, which is a cylindrical component with a bored hole that matches the shaft diameter. The hubs may have keyways or splines to provide additional torque transmission.

- Center Section: The center section of the coupling sits between the two hubs. It is often a split cylindrical sleeve with threaded holes on its outer surface.

- Clamping: To assemble the clamp coupling, the two hubs are placed on the respective shafts, and the center section is inserted between them. Then, bolts are inserted through the holes in the hubs and screwed into the threaded holes of the center section. As the bolts are tightened, the center section is drawn inward, creating a compressive force on the shafts and the hubs, thus firmly holding them together.

- Frictional Connection: The clamping force between the center section and the shafts creates a frictional connection. This frictional force allows the coupling to transmit torque and rotational motion from one shaft to the other.

Advantages:

Clamp couplings offer several advantages:

- Easy and quick installation, requiring minimal tools and no special skills.

- Simple design and cost-effective manufacturing.

- High torque transmission capacity, making them suitable for various industrial applications.

- Zero backlash, ensuring accurate and precise motion transfer.

- Can accommodate different shaft sizes and materials, providing flexibility in design.

Applications:

Clamp couplings find application in a wide range of industries and mechanical systems, including:

- Power transmission in industrial machinery and equipment.

- Robotics and automation systems.

- Printing and packaging machines.

- Material handling equipment.

- Pumps and compressors.

- Conveyor systems.

Overall, clamp couplings are a reliable and versatile solution for connecting rotating shafts and transferring power in various mechanical setups.

editor by CX 2024-04-13

China Shenzhen Custom Made CNC Machined Automotive/Aumobile/Motorcycle/Ship/Boat/Machines Metal Stainless Steel/Brass/Aluminum Shaft Coupling coupling beam

Product Description

HangZhou Custom produced CNC machined automotive/aumobile/motorcycle/ship/boat/devices Metallic stainless steel/brass/aluminum shaft coupling

Click right here and specify your inquiry, speak to us to get an online estimate now!

How to get a estimate?

1. First: Email us and provide your 3D drawing/2nd drawing to us to estimate.

two. Next: Permit us know the required materials, floor finish and special tolerance requirements, quantity data, we are going to arrange for our engineer to evaluation your drawings and estimate quickly!

Observe: Workable 3D Drawing Formats: Action/IGS/X_T/STL/SOLIDWORKS etc, 2d Drawing with PDF will do.

Undertaking Assistance: Free of charge Sample Supplied Ahead of Production commences

Examples assignments

What we can supply

| Rewards | »Free sample provided just before production »Good machining quality and warm service »Reasonable Pricing and excellent high quality offered »Competitive delivery expense service with price cut sometimes »MOQ 1PCS and small amount purchase recognized, mass production supported »Professional engineering support when any modification needed »Any turnkey assembly or customized bundle demands, we’ll meet your demands! |

|||||

| Products |

»20 sets of CNC turning machines »30 sets of the most technologically advanced machining CNC milling equipment »25 sets of Multi-Spindle Japan Precision Swiss CNC lathes |

|||||

| RFQ | Customer Inquiry →Engineering Conversation →Cost Examination →Sales Examination →Quote to Buyer » 1-3 Function Times Only » Submit RFQ with full professional conditions |

|||||

| Sample Making | Sample Purchase → Engineering Assessment → Sample Program to Client → Sample Status Tracking → Submit Samples with Doc. » Sample L/T: 1 7 days » Ongoing Sample Status Monitoring » Comprehensive Documents for sample approval |

|||||

| Order Management | CRM Program → Open Order Verify → Logistic Arrangement. » Manufacturing L/T: 2-4 wks » Weekly Open Purchase Confirm » Chosen 3PL Service to Buyers |

|||||

| Quality Manage | Certificates: RoHS, ISO9001:2008, SGS. IQC → IPQC → OQC/FQC → Quality Complain Feedback → Audit & Instruction. » Plant Audit and Qualified by entire world renowned organization » Rigorous Top quality Administration Method with Traceability |

|||||

| Application | »Aerospace »Automotive »Lighting fittings »Motorbike »PhotoGear »EDC Equipment » Marine »Office products »Home appliance »Medical tools »Telecommunication »Electrical & Electronics »Fire detection system, and so on. |

|||||

Creation data

one). Content Capabilities: Subsequent GB, DIN, and ISO and implementing great good quality selfmade and import materials, we have currently presented single/assembly items for global buyers mostly from the Usa and Europe, and so on.

| Stainless Metal | SS201, SS301, SS303, SS304, SS316, SS416 and so on. |

| Steel | Gentle steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45#, and so forth. |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H62, H68, H80 and so forth. |

| Copper | C11000, C12000, C12000 C36000 and so forth. |

| Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 and so forth. |

| Iron | A36, 45#, 1213, 12L14, 1215 and many others. |

| Plastic | Abs, Personal computer, PE, POM, Delrin, Nylon, PP, PEI, Peek and so on. |

two). Good quality control:

*We have specialized QC testers to check the top quality of the products according to distinct customers’ specifications. Generally, it is a random inspection, and we also supply 100% inspection at a affordable price if needed.

*We have IQC to check the dimensions and surface of the incoming material

*We have PQC to inspect complete-system during the manufacturing processing

*We have FQC to examine all the anodizing/plating and other finishes’ products from our supplier and continue with the professional good quality and physical appearance inspection ahead of transport.

3).Surface Finish: sandblasted/standard and difficult anodized finish/polish/coating/polish/passivation/plating/brush/warmth treatment method/fantastic glass beads/grounding/tumbled complete , and so forth. Far more detailed information for distinct content components is beneath,

|

Aluminum components |

Brushing Polishing Distinct Anodized Shade Anodized Sandblast Anodized Chemical Movie |

| Stainless Metal elements | Polishing Passivated Sandblasting Plating |

| Metal Elements | Zinc plating Oxide Black Nickel plating Chrome plating Carburized Heat remedy Powder Coated |

| Plastic Components | Chrome plating Sharpening |

4). Payment terms: T/T payment. The Sample order is paid by complete payment Mass manufacturing with get quantity exceeding can be paid a 50% deposit prior to generation, and stability paid out before shipping.

five). Generation routine: Usually, it normally takes 5~10 doing work days for sample creation fifteen~20 operating times for mass creation days, it is dependent on your design, straightforward areas can be created quickly, the difficult design and style elements would consider us more machining time.

six). Machining ability: 30 sets of the most technologically innovative machining CNC milling devices, twenty sets of CNC turning devices, 25 sets of Multi-Spindle Japan Precision Swiss CNC lathes, and 4 sets of 2d &3D CMM (graphic measuring instrument) high quality handle equipment 3 QC staff, enabling CNC Manufacturing to provide exact components in the tightest of tolerances, guaranteeing the highest quality outcomes to fulfill distinct

customers’ demands.

7). Tolerance: +/- .02mm (for Metal shaft), +/-.03mm ( for plastic), for particular tolerance requirements, make sure you point them out in the e-mail, we will Check out if it really is possible to make it after studying it.

8). Packing & Delivery way:

one. Packing Element: Each item is packed with plastic preservative, EPE, foam plastic bag, Carton outside, wooden situation or iron circumstance or as per the customer’s specific requirement. Apart from, the customized package will take a 7 days to put together in progress.

two. Shipping Element: the quick Global Transport time will take 3 ~5 functioning days by DHL/UPS/FedEx, sluggish shipping time takes 7~ 8 doing work times by DHL/UPS/FedEx/TNT, and so on.

3. Delivery alternatives:

one) -100kg: specific&air freight precedence,

two) >100kg: sea freight precedence,

3) As for every custom-made technical specs

About us

Complete-service precision CNC machining providers for prototypes and brief and lower to large creation operates. Capabilities are CNC milled and turned metallic elements and assemblies. Supplies labored with incorporate aluminum, brass, copper, stainless, metal, iron, other precious metals, and other plastic components. Guide occasions are 2 to 3 months for prototypes and 4 to 6 months for creation operates. Crisis and hurry services are obtainable. Industries served incorporate aircraft and aerospace, consumer electronics, automotive, equipment fittings, audio products, EDC equipment, computer, and Secondary processes this kind of as anodizing, sandblasting, blackening, grinding, honing, heat dealing with, powder coating, passivation, polishing, plating, and brushing are also offered.

We put higher interest and energy into all of the function that we do. Each and every part that comes off our equipment is an extension of us. We just take great delight in bringing machining CZPT to our consumers. The amazing high quality elements we machined below will be your greatest choice to find a supplier!

Customer’s comment

Want to know a lot more about us? E-mail us now!

| After-sales Service: | Email Us Anytime If Any Problems |

|---|---|

| Warranty: | Email Us Anytime If Any Requirements |

| Condition: | New |

| Certification: | CE, RoHS, GS, ISO9001 |

| Standard: | DIN, Custom Metal Parts & Free Sample Offered |

| Customized: | Customized |

###

| Samples: |

US$ 150/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

|---|

###

| Advantages | »Free sample offered before production »Good machining quality and warm service »Reasonable Pricing and outstanding quality provided »Competitive shipping cost service with discount sometimes »MOQ 1PCS and small quantity order accepted, mass production supported »Professional engineering service when any modification required »Any turnkey assembly or customized package requirements, we’ll meet your demands! |

|||||

| Equipment |

»20 sets of CNC turning machines; »30 sets of the most technologically advanced machining CNC milling machines; »25 sets of Multi-Spindle Japan Precision Swiss CNC lathes |

|||||

| RFQ | Customer Inquiry →Engineering Communication →Cost Analysis →Sales Analysis →Quote to Customer » 1-3 Work Days Only » Submit RFQ with complete commercial terms |

|||||

| Sample Making | Sample Order → Engineering Review → Sample Plan to Customer → Sample Status Tracking → Submit Samples with Doc. » Sample L/T: 1 week » Continuous Sample Status Tracking » Complete Documents for sample approval |

|||||

| Order Management | CRM System → Open Order Confirm → Logistic Arrangement. » Production L/T: 2-4 wks » Weekly Open Order Confirm » Preferred 3PL Service to Customers |

|||||

| Quality Control | Certificates: RoHS, ISO9001:2008, SGS. IQC → IPQC → OQC/FQC → Quality Complain Feedback → Audit & Training. » Plant Audit and Qualified by world famous company » Strict Quality Management Procedure with Traceability |

|||||

| Application | »Aerospace »Automotive »Lighting fittings »Motorbike »PhotoGear »EDC Tools » Marine »Office equipment »Home appliance »Medical equipment »Telecommunication »Electrical & Electronics »Fire detection system, etc. |

|||||

###

| Stainless Steel | SS201, SS301, SS303, SS304, SS316, SS416 etc. |

| Steel | Mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45#, etc. |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H62, H68, H80 etc. |

| Copper | C11000, C12000, C12000 C36000 etc. |

| Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

| Iron | A36, 45#, 1213, 12L14, 1215 etc. |

| Plastic | ABS, PC, PE, POM, Delrin, Nylon, PP, PEI, Peek etc. |

###

|

Aluminum parts |

Brushing Polishing Clear Anodized Color Anodized Sandblast Anodized Chemical Film |

| Stainless Steel parts | Polishing Passivated Sandblasting Plating |

| Steel Parts | Zinc plating Oxide Black Nickel plating Chrome plating Carburized Heat treatment Powder Coated |

| Plastic Parts | Chrome plating Polishing |

| After-sales Service: | Email Us Anytime If Any Problems |

|---|---|

| Warranty: | Email Us Anytime If Any Requirements |

| Condition: | New |

| Certification: | CE, RoHS, GS, ISO9001 |

| Standard: | DIN, Custom Metal Parts & Free Sample Offered |

| Customized: | Customized |

###

| Samples: |

US$ 150/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

|---|

###

| Advantages | »Free sample offered before production »Good machining quality and warm service »Reasonable Pricing and outstanding quality provided »Competitive shipping cost service with discount sometimes »MOQ 1PCS and small quantity order accepted, mass production supported »Professional engineering service when any modification required »Any turnkey assembly or customized package requirements, we’ll meet your demands! |

|||||

| Equipment |

»20 sets of CNC turning machines; »30 sets of the most technologically advanced machining CNC milling machines; »25 sets of Multi-Spindle Japan Precision Swiss CNC lathes |

|||||

| RFQ | Customer Inquiry →Engineering Communication →Cost Analysis →Sales Analysis →Quote to Customer » 1-3 Work Days Only » Submit RFQ with complete commercial terms |

|||||

| Sample Making | Sample Order → Engineering Review → Sample Plan to Customer → Sample Status Tracking → Submit Samples with Doc. » Sample L/T: 1 week » Continuous Sample Status Tracking » Complete Documents for sample approval |

|||||

| Order Management | CRM System → Open Order Confirm → Logistic Arrangement. » Production L/T: 2-4 wks » Weekly Open Order Confirm » Preferred 3PL Service to Customers |

|||||

| Quality Control | Certificates: RoHS, ISO9001:2008, SGS. IQC → IPQC → OQC/FQC → Quality Complain Feedback → Audit & Training. » Plant Audit and Qualified by world famous company » Strict Quality Management Procedure with Traceability |

|||||

| Application | »Aerospace »Automotive »Lighting fittings »Motorbike »PhotoGear »EDC Tools » Marine »Office equipment »Home appliance »Medical equipment »Telecommunication »Electrical & Electronics »Fire detection system, etc. |

|||||

###

| Stainless Steel | SS201, SS301, SS303, SS304, SS316, SS416 etc. |

| Steel | Mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45#, etc. |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H62, H68, H80 etc. |

| Copper | C11000, C12000, C12000 C36000 etc. |

| Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

| Iron | A36, 45#, 1213, 12L14, 1215 etc. |

| Plastic | ABS, PC, PE, POM, Delrin, Nylon, PP, PEI, Peek etc. |

###

|

Aluminum parts |

Brushing Polishing Clear Anodized Color Anodized Sandblast Anodized Chemical Film |

| Stainless Steel parts | Polishing Passivated Sandblasting Plating |

| Steel Parts | Zinc plating Oxide Black Nickel plating Chrome plating Carburized Heat treatment Powder Coated |

| Plastic Parts | Chrome plating Polishing |

What Is a Coupling?

A coupling is a device that connects two shafts together. It transmits power from one to the other and is used to join rotating equipment. It can also allow for some degree of misalignment and end movement. It is used in mechanical engineering and manufacturing. To learn more about couplings, read this article. Mechanical connection between two objectsThe present invention relates to a method and assembly for forming a mechanical connection between two objects. The methods of this invention are suitable for connecting both solid and hollow objects. For example, the method can be used to make mechanical connections between two cylinders. This method is particularly useful for connecting two cylinders that are positioned near each other.

Mechanical connection between two objectsThe present invention relates to a method and assembly for forming a mechanical connection between two objects. The methods of this invention are suitable for connecting both solid and hollow objects. For example, the method can be used to make mechanical connections between two cylinders. This method is particularly useful for connecting two cylinders that are positioned near each other.

Absorbs vibration

A coupling insert is a part of a vehicle’s drivetrain that absorbs vibrations. These inserts are designed to prevent couplings from moving out of phase. However, the coupling inserts themselves can wear out and need to be replaced. Universal joints are an alternative if the coupling is out of phase by more than one degree. In addition, internal bearings in the coupling need to be lubricated and replaced when they begin to show signs of wear.

Another embodiment of the invention includes a flexible coupling 25 that includes rearwardly-extending lugs that extend toward the coupling member 23. These lugs interdigitate with corresponding lugs on the coupling member 23. They are spaced circumferentially. A first elastic member 28 is interposed between lugs 26 and 27, and is adapted to yield in a counterclockwise direction. As a result, it absorbs torsional vibrations.

Blocks heat transfer

Thermal coupling occurs when a solid block is thermally coupled to the air or fluid passing through it. The amount of heat transferred through a solid block depends on the heat transfer coefficients of the materials. This paper presents a numerical model to understand how heat transfers through different block materials. This work also describes the thermal resistance network for a one-dimensional block.

In some cases, thermal coupling increases the heat transfer mechanism. As illustrated in FIG. 1D, a heatpipe coupler 112 couples two heatpipes 110-1 and 110-2. This configuration allows the pipes to be coupled to the heat source and to the condenser. In addition, the heat pipe couplers may have bellows at the ends to help facilitate linear motion.

Thermal coupling is achieved by ensuring that at least one block is made of a material with a lower thermal expansion coefficient than the annulus. Ideally, the block’s mean thermal expansion coefficient is at least twenty percent lower than the annulus’s mean thermal expansion coefficient. This ensures that the thermal coupling between the two parts is as efficient as possible.

Another type of thermal coupling is achieved by using flexible elements. These are often washers or springs. These components allow the blocks to maintain physical contact with the post 55, which means that the heat transfer is more efficient even at higher temperatures. The flexibility of these elements also makes it possible to choose an element that will not impede assembly.

Protects rotating equipment

A reliable, long-lasting coupling system can reduce the risk of damage to rotating equipment. Designed to protect against torque overload and wear, Voith torque-limiting couplings provide outstanding safety and reliability. As a result, they can deliver maximum performance and minimize equipment downtime. In addition to their long-term benefits, these solutions are ideal for applications where safety and reliability are of paramount importance.

A good coupling provides many advantages, including the ability to transmit power, compensate for axial movement, and absorb shock. It is essential to choose the proper coupling for your application based on the basic conditions of your rotating equipment. For example, if you have two shafts with parallel rotation axes, you should choose a parallel coupling. Otherwise, you should use an angular coupling.

Torque-limiting couplings can also provide protection for rotating equipment by disengaging at a specific torque level. This protects the drive shaft from undergoing catastrophic failure. Torque limiters are particularly helpful for high-value equipment. By preventing catastrophic failure, you can avoid expensive repairs and minimize equipment downtime.

Coupling guards are easy to install and provide effective protection for rotating equipment. These covers are made of sheet metal bent to fit over the shaft. They are durable and easy to remove when necessary. This type of guard can prevent employees from catching their hands, tools, or loose clothing on motor coupling components.

editor by CX 2023-03-29